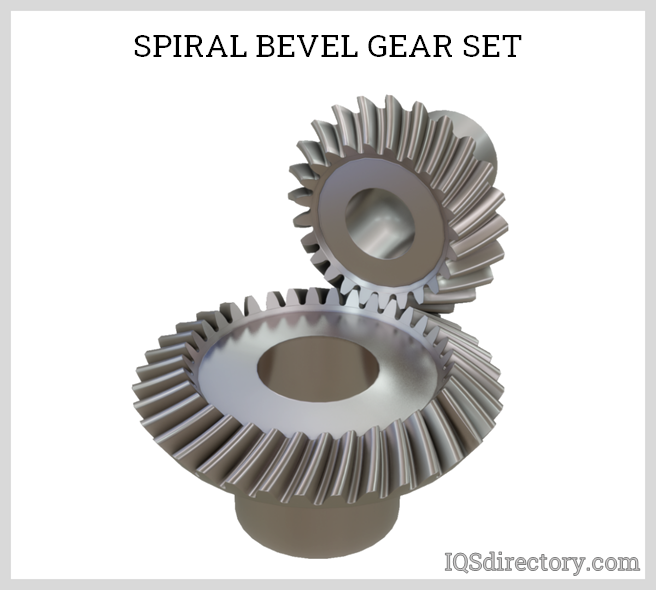

So the gear face line and the gear pitch line are coincident. Spiral bevel gears Figure 5716 have curved oblique teeth that contact each other gradually and smoothly from one end of the tooth to the other meshing with a rolling contact similar to helical gears.

Fig 8 12 Left Hand Zerol Bevel Gear

To develop the selected Gear 9.

. Bevel gears are most often mounted on shafts that are 90 degrees apart but can be designed to work at other angles as well. Bevel Gear Terminology. Figure 1 shows an illustration of a Zerol bevel gear set and a cross-sectional drawing.

Sub-zero temperatures using special application. The continuous pitch line contact of spiral bevel and hypoid gears makes it practical to obtain smooth performance with a smaller number of teeth in the pinion than is possible with straight or Zerol bevel gears. Per definition Zerol gears are manufactured in a single-indexing process applying a standard tooth taper as shown in.

There are four types of bevel gears are available in general mechanical design. The related zerol bevel gear design pageyou can find more similar zerol bevel gear design from YQ-ChinaTransmissionschina zerol bevel gear design manufacturerWe provide you excellent products buy services. The calculation equations of Table 8-2 for Gleason straight bevel gears are applicable.

AGMA 20203 1965 System for ZEROL Bevel Gears AGMA 20803 1979 System for Straight Bevel Gears AGMA 20904 1982 System for Spiral Bevel Gears AGMA 33001 1972 Design Manual for Bevel Gears The standard was revised in 1994 to include all currently used hypoid design methods. Smooth and low-noise power transmission between non-parallel shafts at almost any angle or speed. In general when the concept of bevel gear is spoken people generally think of the straight type of bevel.

By nature bevel gear design is highly complex. The rule of thumb curvature shown here can be applied to either the pinion or the gear and works for Zerol bevel spiral bevels and hypoids. DESIGN AND ANALYSIS OF A COMPOSITE BEVEL GEAR IN AN AUTOMOBILE DIFFERENTIAL GEAR BOX.

Zerol bevel gears are very similar to a typical bevel gear. The force on the teeth of zerol bevel gears are the same as straight bevel gears. Straight Bevel Gear Spiral Bevels Miter Zerol Anti-Back Lash Gears more Download Guide Bevel gears are used extensively in a wide variety of industries and mechanical operations due to the most important advantage they offer.

Usually the manufacturer of the bevel gear. While their teeth are curved the ends section of each tooth are coplanar with the axis and the middle part of each tooth is circumferentially swept around the gear. On a hypoid bevel gear the pitch angle is hyperbolic instead of conical and the pinion can be offset either below or above the gear center.

Precision Gears Per Design Bevel Sets Parallel Axes Gears. Spiral bevel and hypoid gears are also recommended for large reduction ratios to reduce the overall size of the installation. Hypoid type spiral type zero spiral type and straight type bevel gears.

The teeth are curved teeth at an angle allowing tooth contact to be gradual and smooth. In essence Zerol Bevel Gears are Spiral Bevel Gears with a spiral angle of zero. A left-hand gear always mates with a right-hand pinion.

Bevel gears can include straight spiral Zerol hypoid and Spiroid to address the differences between each one is beyond the scope of this guide. Figure 814 Zerol Bevel Gear At the point on the tooth line where it intersects the pitch cone generating line at angle β if the perpendicular cross section is drawn then the equivalent spur gears number of. For miter gears input and output bevel gears have the same number of teeth.

CALL US 630 543-6640. Zerol Bevel Gear Patented gear with curved teeth but with a zero spiral angle Axial thrust loads are less than spiral bevel gear Often used instead of straight bevel gears Shigleys Mechanical Engineering Design. The pitch surface of bevel gears is a cone.

A True b No larger contact ratio c Zero contact d None of the listed Answer. For peripheral speeds upto 1000 feet per minute where maximum smoothness and quietness are not primary considerations straight and Zerol bevel gears are recommendedFor such applications plain bearings may be used for radial and axial loads although the use of anti-friction bearings are always preferable. They happen to fall in the category of spiral bevel gears.

Gears and Pinions - Manufacturer of bevel gears spiralangularhypoidstraight bevel gearsspline shaftsquality design. The main objectives of this project work are- I. To solve a problem related to Bevel Gear II.

They also should take care again of the rule of hands. 854 Gleason Zerol Spiral Bevel Gears When the spiral angle β m 0 the bevel gear is called a Zerol bevel gear. A reliable source over 50 years for precision Bevel and Parallel Axes Gears.

Ate the desired crowning see also General Explanation of Theoretical Bevel Gear Analysis. Some typical bevel gear The most common gear-cutting processes include hobbing broaching milling and grinding. Their characteristics are summarized below.

A True b False Answer. All the circular arc gears other than Zerol gears are sometimes called helical bevel gears. Bevel gears are gears where the axes of the two shafts intersect and the tooth- bearing faces of the gears themselves are conically shaped.

They have the combination of advantages of straight and spiral bevel gears. Zerol bevel gears can be introduced as a kind of spiral bevel gears which also have special teeth but with a zero. Zerol gears give lesser contact ratio.

Serving customers in the Aerospace and Industrial Markets. Straight and Zerol Bevel gear. Because these types of bevel gears are basically conical in shape they all have an optimum position for best performance.

STRAIGHT BEVEL GEAR SPIRAL BEVEL GEAR ZEROL BEVEL GEAR HYPOID BEVEL GEAR LECTURE from DESIGN 2 at Polytechnic University of the Philippines. Zerol bevel gears trade marked by the Gleason Co are spiral bevel gears in which the spiral angle is zero at the middle of the face width. Left and right of a pair must be matched.

Gears are commonly made from metal plastic and wood. Figure 8-12 is a left-hand Zerol bevel gear. Figure 1Zerol bevel gear geometry.

A zerol bevel gear also has curved teeth but they are not angled in a spiral so the teeth align with the axis. Zerol gears are straight bevel gears with zero spiral angle. A right-hand gear always mates with a left-hand pinion.

To design that Bevel Gear III. Hypoid bevel gearsThese gears are similar to spiral bevel except that the pitch surfaces are hyperboloids rather than cones. Spiral bevel gears are smoother and quieter in operation than straight bevel gears primarily due to a design that.

In automotive Industrythe differential gear plays an important role in power transmission as well as in the handling of the automobileIt transmits torque through three different shafts.

Bevel Gear What Is It How Does It Work Types Uses

Bevel Gear What Is It How Does It Work Types Uses

Zerol Bevel Gear ब वल ग यर In Kurichi Coimbatore Prakash Gears Id 6857852497

Pdf Design And Analysis Of A Spiral Bevel Gear Semantic Scholar

Spiral Bevel Gear Mesh Download Scientific Diagram

Yinxin Teeth Hardened Ground Zerol Bevel Gears For Vehicle Differential Buy Ground Zerol Bevel Gears Bevel Gear Steel Differential Main Gear Product On Alibaba Com

0 comments

Post a Comment